- Product

-

Solutions

-

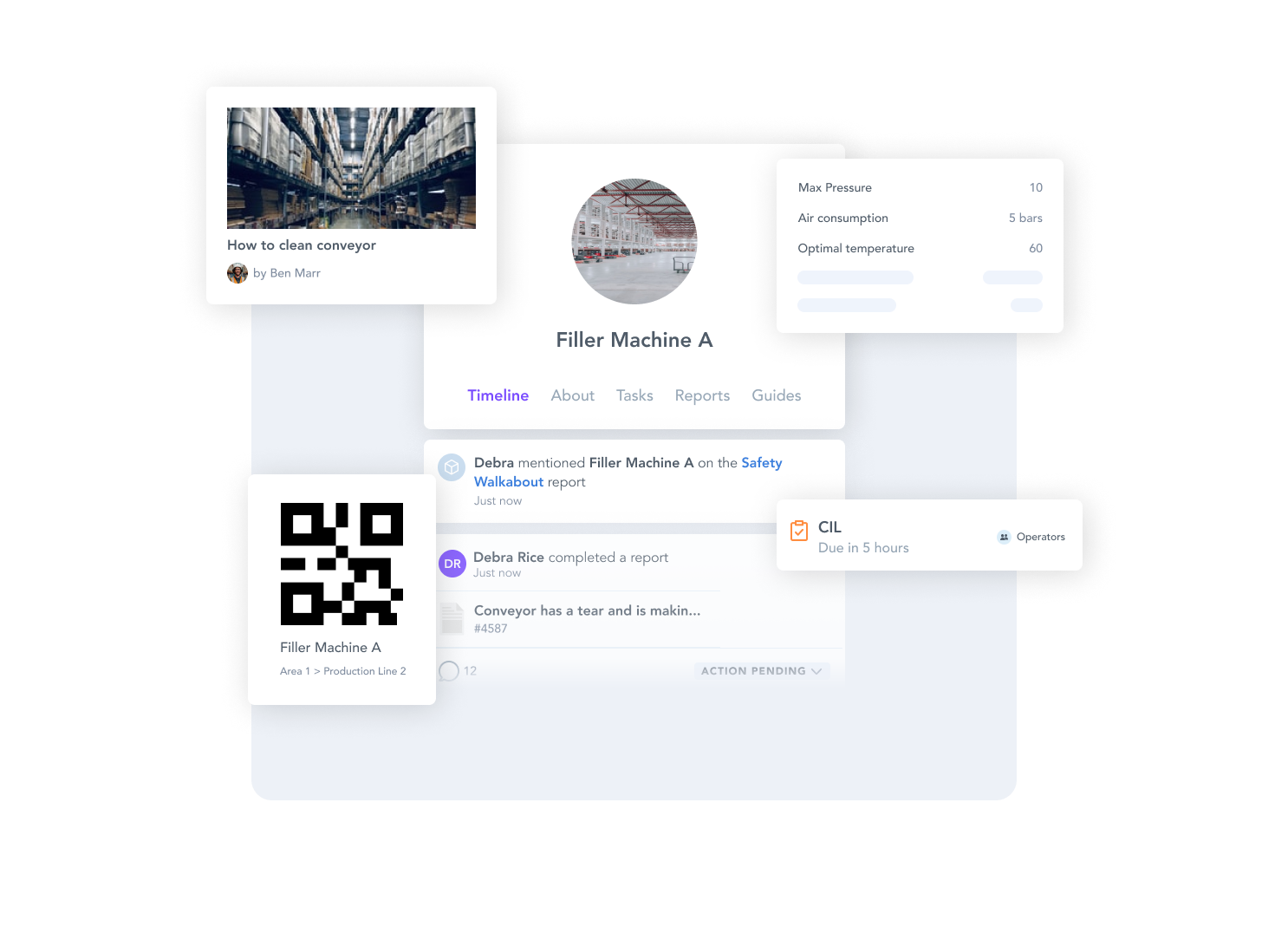

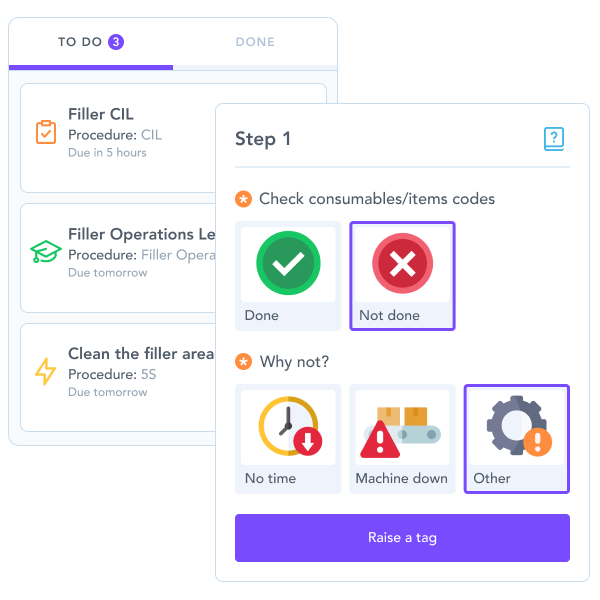

Digital Daily Work

Embed strong operational foundations digitally

-

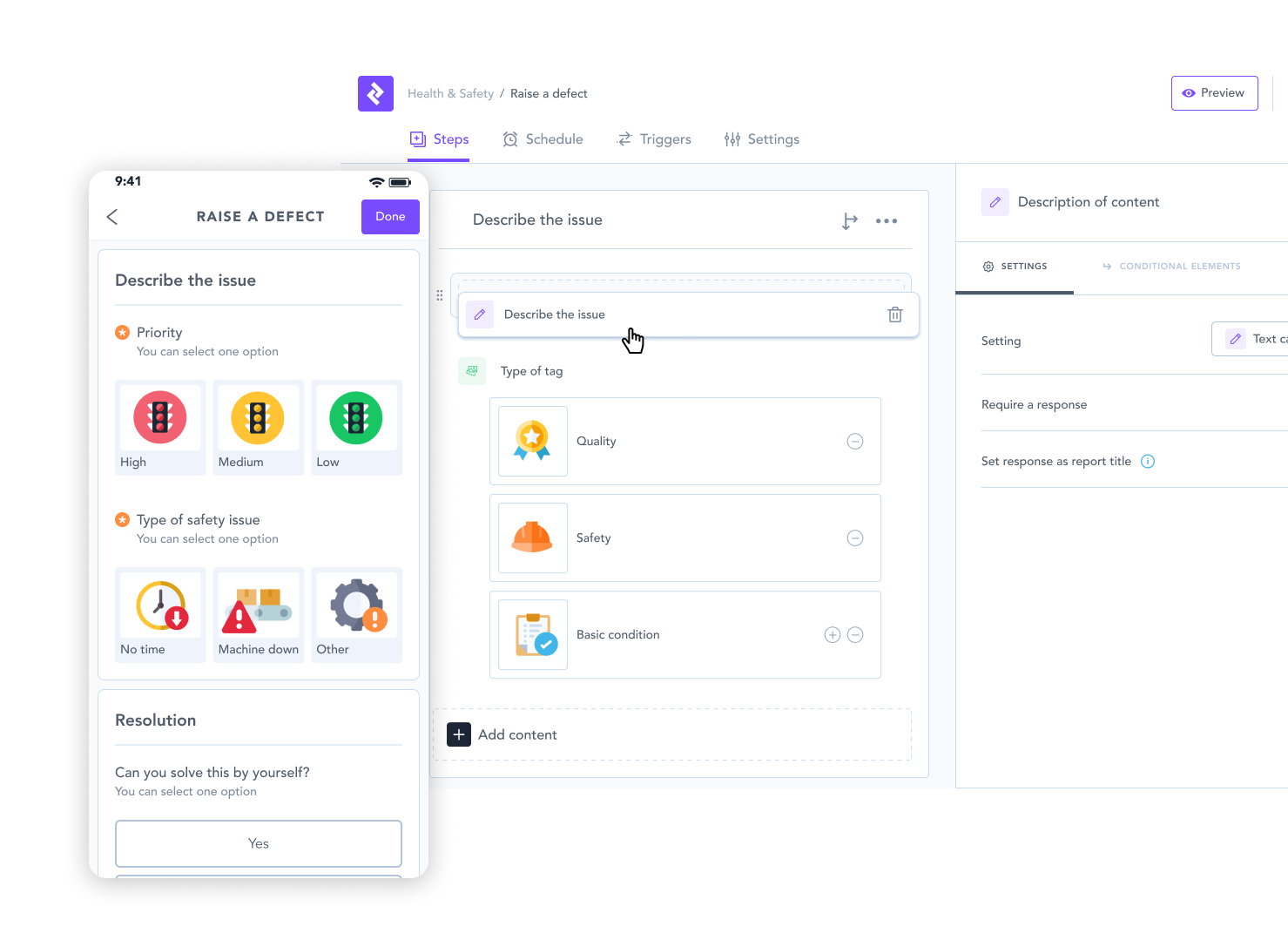

Mobile EHSQ

Reduce risk, improve compliance, and empower a EHSQ culture

-

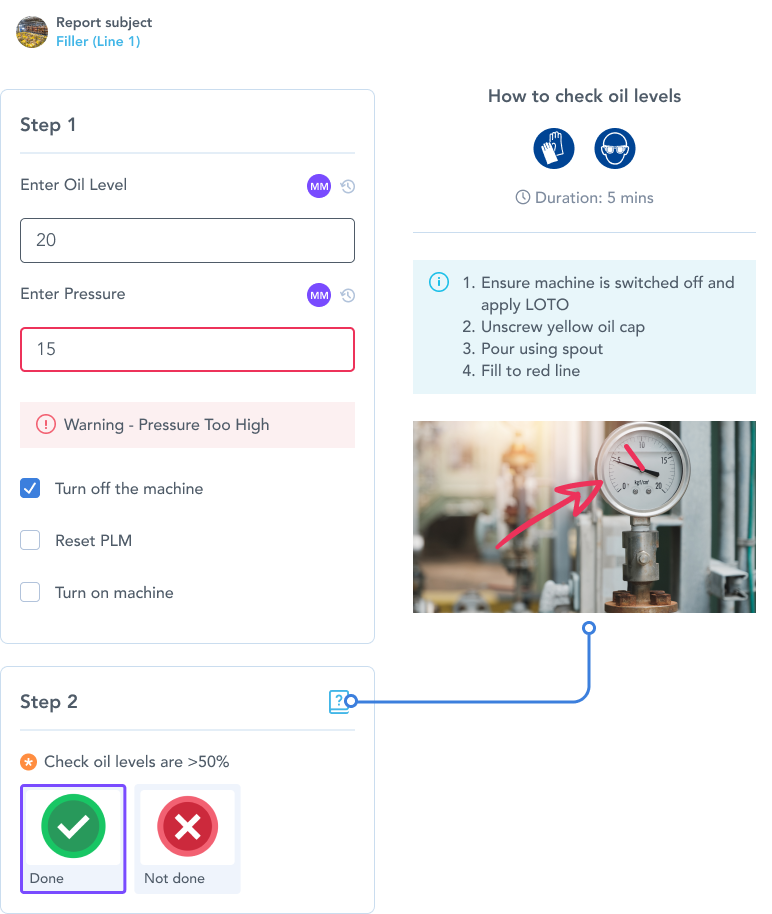

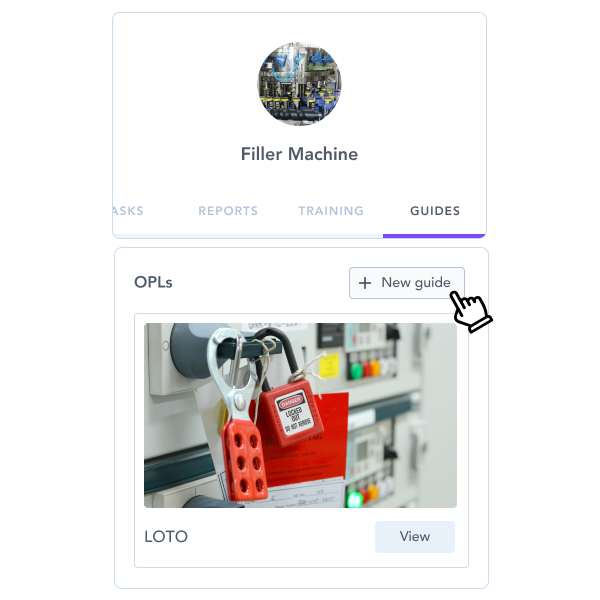

Integrated Asset Care

Enable advanced asset care with IT and OT integration

-

Leadership Value Creation

Turn shop floor improvements into lasting value

-

Job-Specific Training

Onboard and upskill faster

-

- Our Story

- Customers

- News & Insights

- Resources & Downloads